Transforming Production with AI: Enhancing Precision, Efficiency, and Growth.

About Stratix Insight

Stratix Insight, a subsidiary of ATST, is dedicated to advancing the glove manufacturing industry with specialized expertise, innovative machinery, and automation solutions that drive productivity and quality. As a trusted partner, we focus on optimizing every stage of glove production to meet the highest standards and industry demands.

Precision Engineering

Innovative Automation

Industry Expertise

Key Features

Wider Range

Faster Speed

Higher Accuracy

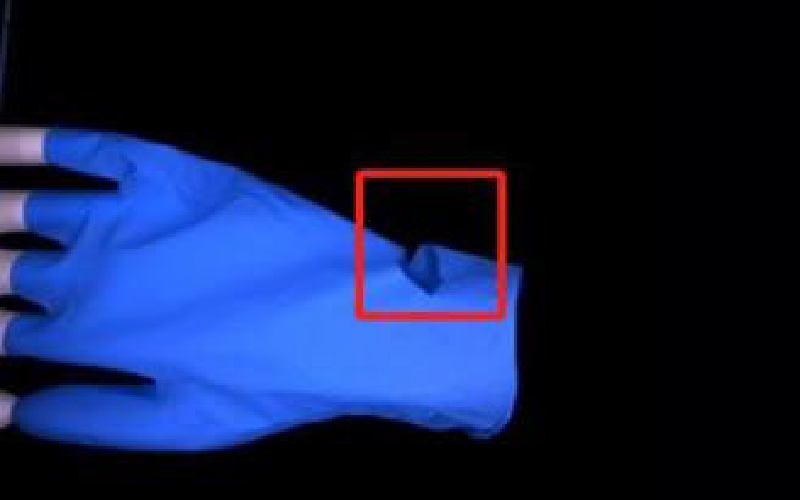

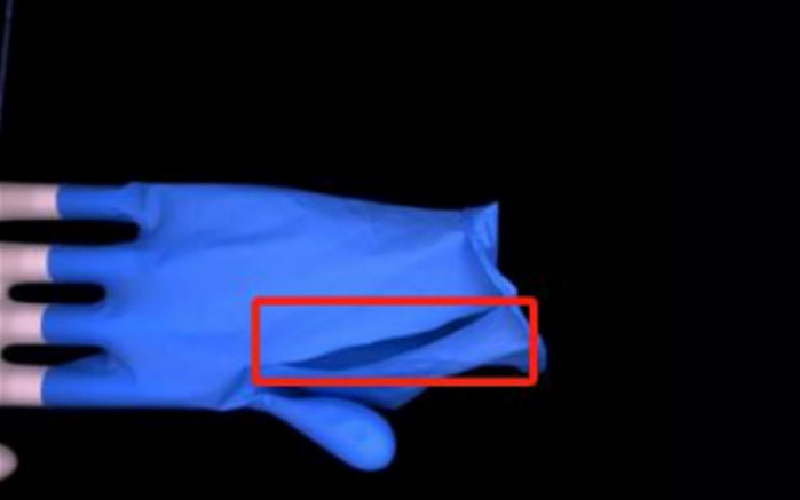

Nitrile Gloves AI Vision Inspection Equipment

To enhance the accuracy and efficiency of glove inspection, Shine Technology has developed and successfully launched the Dual-Mode Nitrile Medical Glove Vision Inspection System.

This equipment employs advanced AI artificial intelligence software to perform comprehensive inspection of gloves in motion, including fingers, palms, and cuffs. It is capable of identifying defective products and removing them.

Detection Scope

Accurately detects oil stains

dirt spots

damage on gloves

Intelligent Sorting Machine

We are delighted to present the Intelligent Sorting Machine, a sophisticated and exceptionally reliable solution meticulously designed to optimize operational efficiency and deliver precise, thorough product sorting. This cutting-edge machine incorporates advanced technology to offer a comprehensive sorting process, establishing new benchmarks in the industry for accuracy and dependability in sorting operations.

Intelligent Sorting Machine

Artificial intelligence software is used to perform all-round inspection of parts and remove them. Through deep learning algorithms, defects are classified, located, alarms are output, and defect images are displayed. At the same time, high-precision cameras are used to measure the size of parts, and those that do not meet the size range will be automatically removed.

Blister Machine

Our blister machine utilizes image vision inspection technology to accurately detect various appearance defects in tablets. By employing advanced AI software, it conducts comprehensive inspections of moving tablets, identifying and removing defective products. Through deep learning algorithms, the system classifies and locates defects, outputs alerts, and displays defect images to ensure quality.

Blister Machine AI Vision Inspection System

Artificial intelligence software is used to perform all-round inspection of parts and remove them. Through deep learning algorithms, defects are classified, located, alarms are output, and defect images are displayed. At the same time, high-precision cameras are used to measure the size of parts, and those that do not meet the size range will be automatically removed.

Intelligent Robot

We offer an extensive range of innovative and reliable conveying and product handling systems designed to move products seamlessly through the production line. Our solutions are engineered to optimize efficiency, ensuring that every stage of the process is streamlined and that your operations run smoothly, from start to finish.

Intelligent Fruit Picking Robot

In fruit and vegetable production operations, the picking and harvesting process accounts for about 40% of the entire operation. The traditional manual picking method is highly labor-intensive and is affected by weather and sunlight restrictions. It not only has low efficiency but also impacts the quality of work, with no guarantee of consistent results. Additionally, the safety hazards during the picking process cannot be ignored. The emergence of unmanned picking robots addresses the current challenges in fruit picking by automating the harvest process. These robots can adapt to environmental changes, ensure work efficiency, and meet the needs of the developing fruit industry.

3D Manipulator

The 3D manipulator is an automated device that can imitate human arm movements and has high flexibility and adaptability. This solution aims to design a 3D manipulator with high precision, fast response and strong load capacity to meet the needs of complex industrial application scenarios. The manipulator will achieve excellent performance through optimized mechanical structure design, electrical control system design and software algorithm design.

Functional Characteristic

Fruit & vegetable identification

Based on deep learning and large-scale image training, it can accurately identify comprehensive information such as fruit and vegetable categories, locations, and confidence levels in pictures.

Robotic arm planning

From forward and inverse kinematics, kinematics to dynamics, from joint coordinate system to Cartesian coordinate system.

Force control hand-eye coordination

Force feedback control combined with visual recognition enables precise grasping of objects.

Hardware Advantage

Low Risk

Algorithm Advantage

Service Advantage

Tech Automated Packing Machine

Quick Model Change

High Efficiency & Stability

Strong Versatility

Suitable for packaging various types of disposable gloves, including snap-close and hinge-lid boxes.

Stacking Firewood Stacking Robot

A fully autonomous agricultural transport vehicle, equipped with proprietary core technology, is capable of performing a range of functions, including handling heavy objects in the field and efficiently transporting agricultural products. This advanced vehicle enhances productivity by automating the transportation process, ensuring timely and safe delivery of goods from the field to their destination, while reducing the need for manual labor and improving overall operational efficiency.

Functional Characteristic

Autonomous positioning and navigation

Equipped with Shengheng intelligent control system, binocular vision is combined with RTK navigation to intelligently plan driving routes and achieve fully automated operations.

Intelligent perception and obstacle avoidance

Front-mounted ultrasonic obstacle avoidance accurately senses obstacles ahead and assists the emergency stop button to achieve safe and reliable motion control.

Convenient operation

Intelligent display of driving route and operating status enables two-hand control and one-button operation.

Air Purge Glove Removal Module

Manual removal of unstripped or half-stripped gloves is inefficient, unstable, and poses safety risks. Our Air-Blowing Glove Removal Module efficiently clears unstripped and half-stripped gloves, achieving a mold-clearing rate of 99%. It’s safe and reliable, with speeds up to 220 gloves per minute.

Program Advantage

No Damage to Hand Molds

Labor Replacement

Fully Automated Glove Layering, Stacking, and Counting Machine

Glove Demolding

Wrist Neatness

Easy Removal

Automated Stacking & Counting

Automatically pulls gloves from the dipping line based on size and quantity for fast, accurate stacking.

High Flexibility

AI Vision Sorting Machine

Integrated Equipment

Remote Control

System Alerts

Defect History Tracking

Advanced Algorithm

Combines traditional algorithms and deep learning for optimized performance

Modular Conveyors

Mini-series belt conveyor (90° and 180° curve belt conveyors)

Roller conveyor series

Poly-V belt driven conveyor

Telescopic conveyor series

Ball-transfer equipment

Skate-wheel conveyor

Vertical reciprocating conveyor

Medium to heavy duty belt conveyor

Flexible chain conveyor

Transfer Conveyors

Top Reason To Choose Us

One Stop Solution Provider

A comprehensive one-stop solution provider with a strong focus on industrial automation, delivering tailored solutions for various manufacturing sectors.

Earth friendly

ATST makes a difference to the environment, without any compromise in protection and performance. An estimation of up to 3000% aggregated production energy can be saved.

Committed people

We are dedicated to fostering enduring, mutually beneficial relationships with our clients, ensuring long-term success and collaboration built on trust and shared goals.

Cost-efficiency

ATST utilised the latest digital transformation, advanced automation and digitization to improve production yields, quality, and efficiency in a cost-effective manner.